1. Purpose

These Terms of Use define the rules governing access to and use of the website www.solutions-cnc.com (hereinafter "the Site").

By accessing and browsing the Site, the user (hereinafter "the User") accepts these Terms without reservation.

2. Site Access

The Site is accessible 24/7, except scheduled interruption for maintenance or force majeure.

The Site editor cannot be held responsible for any temporary interruption or unavailability.

3. Content Use

All content on the Site (texts, images, logos, programs, training materials, etc.) is protected by intellectual property law.

Any reproduction, distribution or exploitation without prior authorization is prohibited.

The User undertakes to use the Site only in a legal framework and in accordance with its purpose.

4. Services Offered

The Site offers in particular:

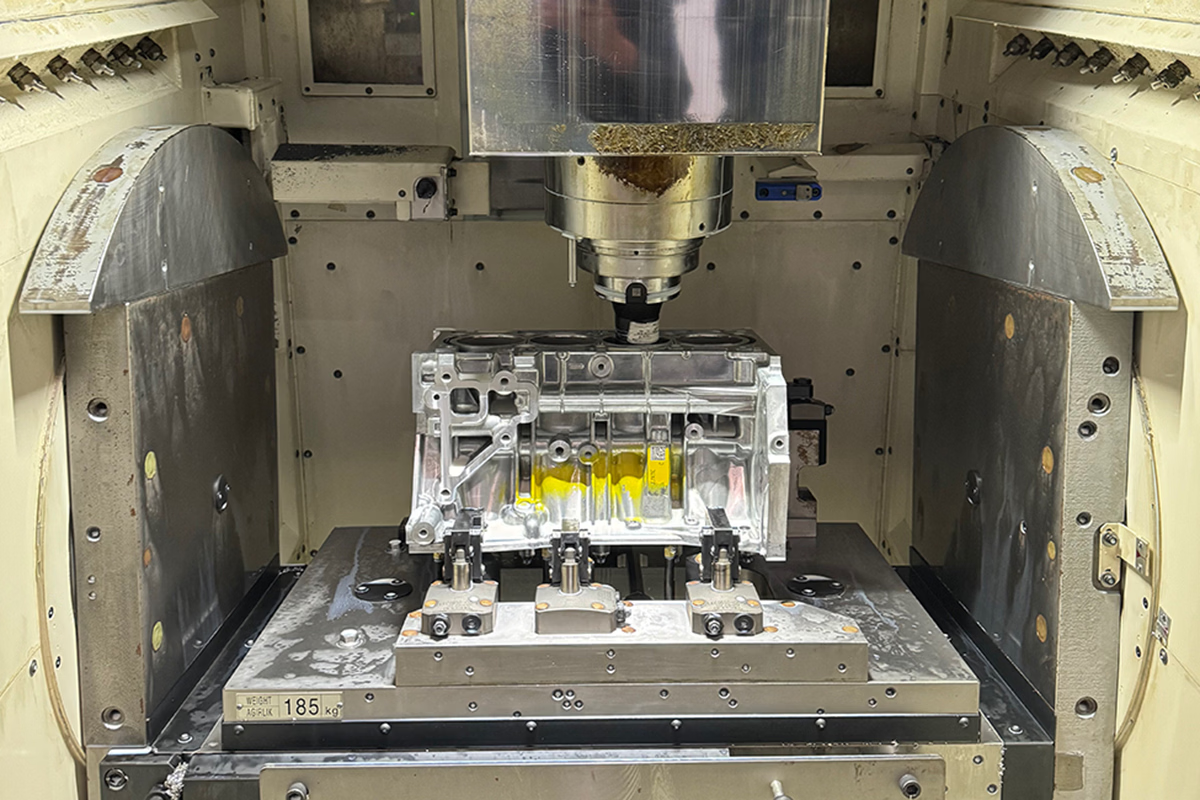

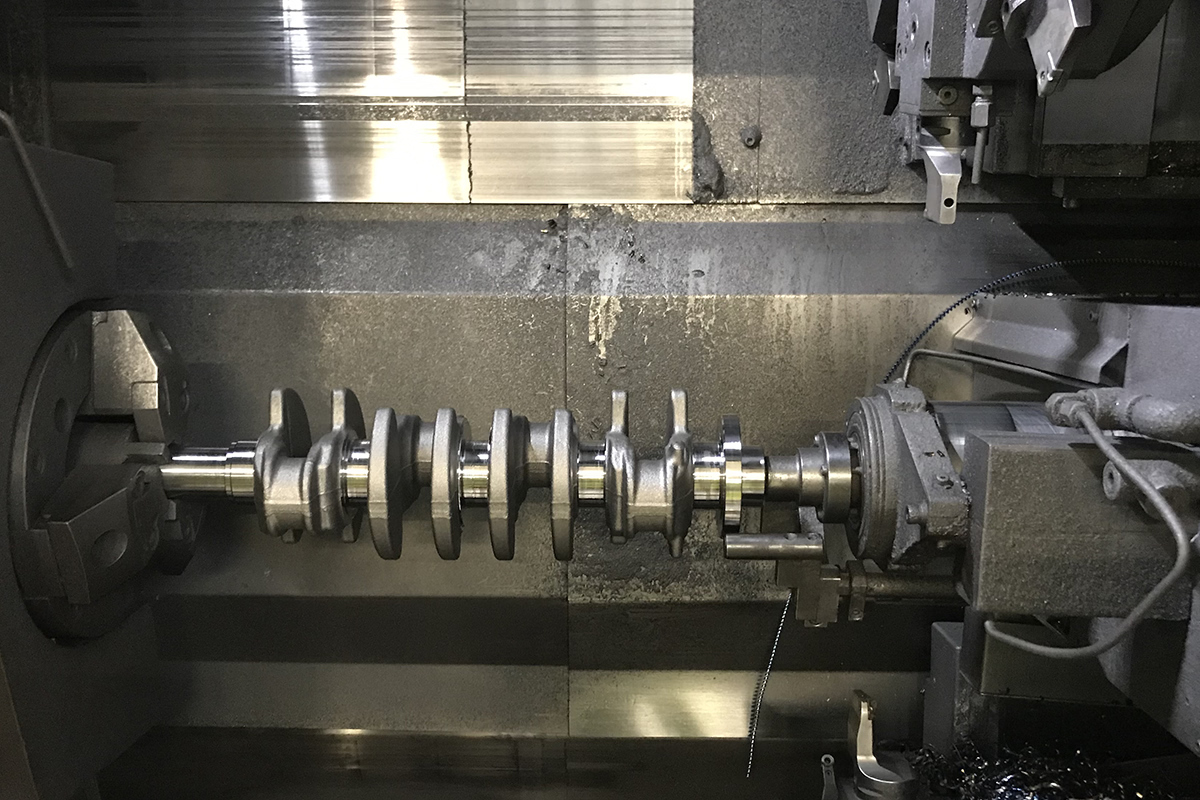

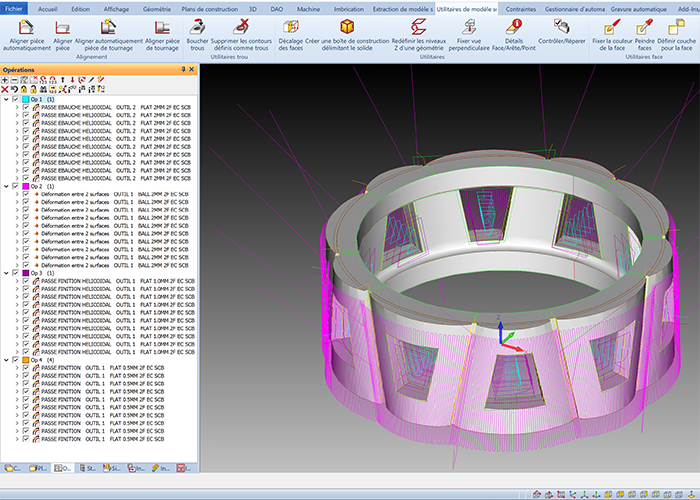

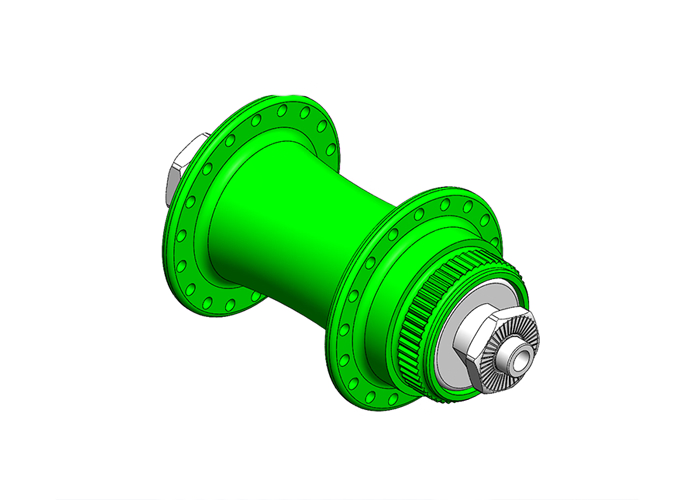

- information on CNC programming,

- training, assistance and sourcing services,

- the possibility to contact for professional services.

This information is provided for information purposes and may change at any time.

5. Responsibilities

The Site editor makes every effort to ensure the accuracy and updating of information. However, no guarantee is given regarding completeness or absence of errors.

The User is solely responsible for the use they make of the available information.

The Site editor cannot be held responsible for direct or indirect damages related to the use of the Site.

6. Hyperlinks

The Site may contain links to third-party sites. The editor exercises no control over these sites and declines all responsibility regarding their content or practices.

7. Personal Data Protection

The use of the Site may involve the collection of personal data (via the contact form, for example). This data is processed in accordance with the Site's Privacy Policy, in compliance with GDPR.

8. Modification of Terms

The Site editor reserves the right to modify these Terms at any time. The User is invited to consult them regularly to be aware of any updates.

9. Applicable Law and Jurisdiction

These Terms are subject to French law. In case of dispute, express jurisdiction is attributed to the courts of the editor's headquarters, except contrary legal provisions.